How Austria became the technology driver in aviation production processes

Research and development cooperation in the production of composite components led to the successful positioning of Austrian expertise and international networking.

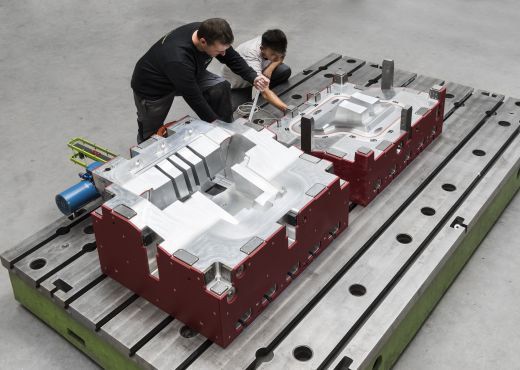

As a result, ALPEX Technologies has built up extensive expertise in tooling and mould making systems for manufacturing fibre-reinforced plastic aviation components. The expertise of Aerospace & Advanced Composites AAC lies in sensor integration, simulation of resin infiltration processes, and online monitoring. The institute Profactor deals with quality assurance methods. At the University of Leoben, the expertise of two chairs is in great demand: the chair of processing of composites deals with process automation and quality assurance in the processing of fibre reinforced plastics, while the chair of automation researches algorithms and embedded cyber-physical systems ("digital twins") for these processes.

The efforts of Dr Horst Schmidt-Bischoffhausen, which brought together the German aviation industry with Austrian system partners in research and development projects, were groundbreaking for many Austrian players.

The manufacturing process field of expertise can be encapsulated by the following Innovation Booster.

Innovation BoosterIndustrialisation of Manufacturing Processes

Civil aviation is expected to double within the next 15 years. The industry is trying to increase the productivity of aircraft production to the same extent, mainly through industrialised and intelligent production processes.

ALPEX Technologies is a tooling system supplier for the manufacturing of fibre composite components in two worlds: aviation and automotive. A circumstance that benefits both industries. ALPEX transfers aviation composite know-how to the automotive industry, whereas automotive automation solutions are important for aviation. Research and development is indispensable for understanding processes and developing appropriate tools. Cooperation between research and industry plays an essential role. For example, on the research side, Aerospace and Advanced Composites AAC is responsible for sensor integration and the simulation of filling and curing processes. The University of Leoben contributes its expertise in the optimisation of processing methods and automation. Their aim is to jointly show the possibilities of an industrial production to the ALPEX aviation industry.

This is unique:

- Worldwide one-of-a-kind know-how of the process

- Combination of solutions from the aviation and automotive sectors

- Simulation of complex systems from the basic product to the component

Therein lies potential for development:

- Growing demand for lightweight construction in various industries and applications

- High potential for industrialisation and automation

- Digitisation of manufacturing processes

- Know-how transfer from other industries

Sometimes the unwritten laws of the industry need to be broken in order to get ahead.