HEAT - Heating Paint Based De-icing System for Drive Components and Aircraft Wings

Short Description

Objective

The development of a special heating paint as the basis for a lightweight, simple and flexible de-icing system for aircraft.

Content

A combination of research activities was used for the development, namely 1) the heating paint itself in the form of the formulation of optimised compositions of polymers and conductivity additives, 2) the de-icing system in the form of power supply, electrical contact, and substrate and cover materials, 3) numerical simulation of the icing and de-icing process with special FEM and CFD software pacts, and 4) the study of functional patterns in the icing wind tunnel.

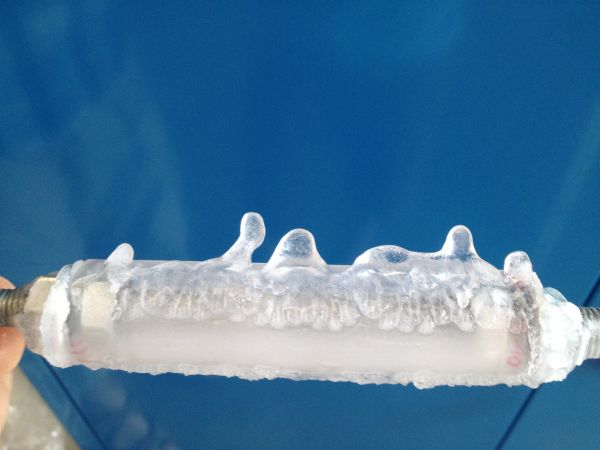

Real-life practical trials were conducted on a prototype propeller on a single-engine general aviation aircraft. It is due to the positive results of the HEAT project, that in-depth research projects (e.g. AntiIce) as well as industrial development contracts (mainly by Villinger GmbH) could be carried out.

Methodology

- Construction of a working prototype the design of which is achieved by means of numerical simulations

- Icing wind tunnel testing of the prototype

Outcome

Tests of the heating system in the icing wind tunnel have been successful; the main focus for the subsequent developments of the project (carried out mainly by Villinger) is the energy consumption and system control.

Aviation Forum Austria 2016: Heat

The video is provided via Youtube , a connection to the servers of Youtube is established (see privacy policy).

Project Partners

- LKR Leichtmetallkompetenzzentrum Ranshofen GmbH - Coordinator

- Aerospace & Advanced Composites GmbH

- FH JOANNEUM GmbH

- qpunkt GmbH

- Villinger GmbH

Funding program: TAKE OFF