FSA - Future Small Aircraft

Short Description

Motivation

The aviation industry is expected to grow very dynamically over the next few decades, with the European Commission forecasting air traffic growth in Europe of 108% by 2020 [1, page 6], which is also reflected in the expected aircraft movements and the number of aircraft in use, with strong growth forecast for general aviation business aircraft in particular.

The globalisation trend towards an increasingly interdependent international economy boosts this growth and the consequent rapidly increasing demand for passenger transport. Due to the ever-growing travel distances with the desired reduction of travel times, transport by motor vehicle is reaching its natural limits. The modal split - the distribution into the different modes of transport - will therefore inevitably shift further and further in the direction of aircraft, as clearly graphically illustrated in Figure 1 of the RTI aviation strategy.

Objectives

- Marketable rapid development

- Affordable aircraft

- Ecological engine utilisation

Content

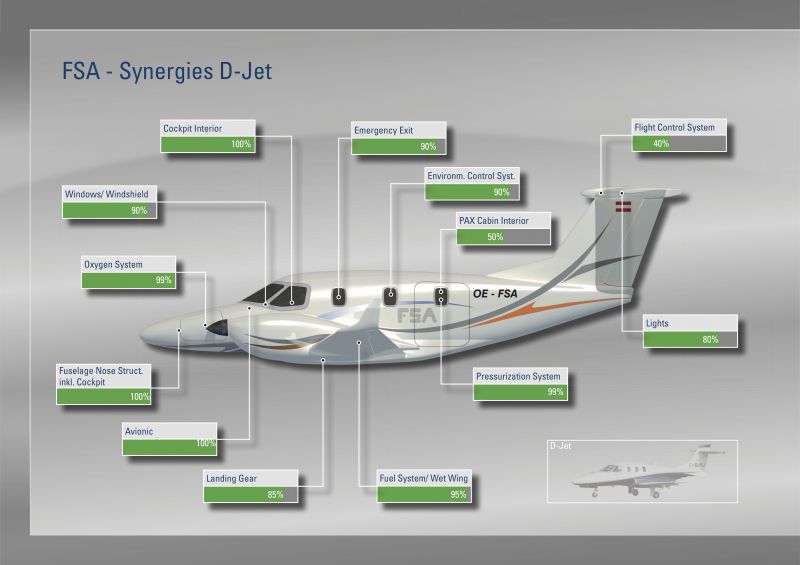

The purpose of this funded project is to ensure the speedy development and realisation of a travel and business aircraft under the guidance of Diamond Aircraft Industries GmbH in Wiener Neustadt and in close cooperation with suppliers (Austro Engine), universities (Kepler University Linz, Technical University Munich) and R & D facilities (Lynx Composites).

The project will enable the Austrian aviation industry to increase its competence in key technology fields and develop human capital through identifying and developing optimal solutions to specific issues, thereby increasing the competitiveness of the Austrian aviation industry in order to enter new high-tech markets. The research focus covers a complete portfolio for general aviation, including innovative technologies, materials, propulsion systems, systems, avionics, as well as development and production processes.

Methodology

Radical weight savings, optimised aerodynamic wing and fuselage layout, manufacturing effort reduction: maximizing range, cruise speed, and payload with low fuel consumption is achieved primarily by minimising aircraft weight.

With the help of a partner, Lynx Composites, the innovative methods for producing composite structures, which are already widespread in commercial aviation, are now being introduced to the area of general aviation. Particularly noteworthy here is the VAP (Vacuum Assisted Process) technology, which minimises the air trapped in the fibre composite components by using a special resin-impermeable membrane, thereby maximising process reliability and component quality. Figure 5 shows this process graphically.

Expected results

Approved prototype at the end of the project period.

Outcome

Several flying prototypes.

Aviation Forum Austria 2016: FSA3

The video is provided via Youtube , a connection to the servers of Youtube is established (see privacy policy).

Project Partners

- Diamond Aircraft Industries GmbH - Coordinator

- Austro Engine GmbH

- JKU Linz

- Lynx Composites GmbH

- PRIME aerostructures GmbH

- qPunkt GmbH

- TEST-FUCHS GmbH

- TTTech Computertechnik AG

- TU München

Funding program: TAKE OFF