IceDrip - Aircraft Anti-icing and De-icing through Assemblies of Conducting Varnish and Functional Coatings

Short Description

Motivation

In previous research projects, the basics of an electrothermal multi-zone de-icing system were investigated. The required amount of energy is too large, especially for small aircraft. The heating system will be equipped with functional surfaces, which should reduce the amount of energy required until this system becomes of interest for small aircraft.

Objectives

- To reduce the energy requirements of an electrothermal de-icing system by combining functional surface coatings and heating paints.

- To further develop and validate simulation models for the design of electrothermal de-icing systems.

- To perform functionality verification in the icing wind tunnel of FH JOANNEUM (small-scale tests).

- To perform the functionality verification of a 1:1 scaled prototype at RTA.

Content

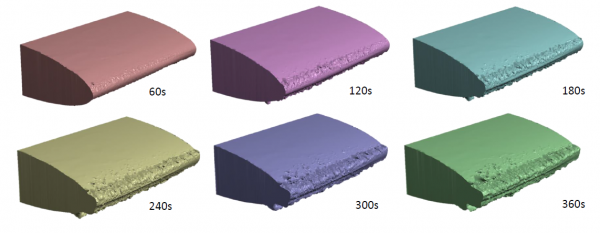

In the current project, the rather promising concept of a discontinuous, electro-thermal de-icer is being investigated. Such a system is substantially more energy efficient than conventional (electro)thermal deicing systems that melt or even vaporise all of the ice accreted.

This discontinuous de-icing concept will be combined in this project with (super)hydrophobic coatings, which have been shown in ongoing projects by partners FHJ, AAC and VIL to be effective in improving ice/water removal from a heated surface.

The main aim of the present project is to significantly increase the already existing energetic advantages of the discontinuous de-icer by means of surface-active coatings, in order to achieve a performance range which would make the system suitable for general aviation aircraft, as well as smaller aircraft, which are equipped with less powerful engines and wiring systems than large aircraft.

Methodology

- Carrying out a targeted literature research and patent analysis.

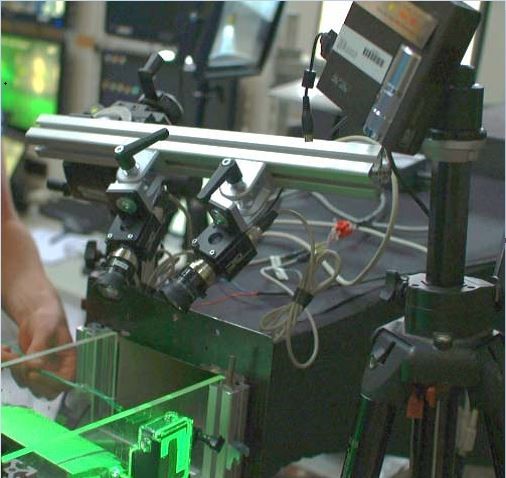

- Small scale tests in the icing wind tunnel of FH JOANNEUM to demonstrate the basic principle.

- Large scale tests at Rail Tec Arsenal with a functional prototype.

- Functionality verification in the icing wind tunnel - proof of concept.

Expected results

-

Production of a functional, heat-resistant surface coating.

-

Functionality verification of the coating using small-sized models in the icing wind tunnel of FH JOANNEUM.

-

Further development of simulation models for the design of de-icing systems.

-

Functionality verification on the 1:1 scaled model at RTA.

-

Herstellung einer funktionalen, hizebeständigen Oberflächenbeschichtung

-

Nachgewiesen Funktion der Beschichtung anhand kleinsaklierter Probekörper im Vereisungswindkanal der FH JOANNEUM

-

Weiterentwicklung der Simulationsmodelle zur Auslegung von Enteisungssystemen

Outcome

Significant energy savings could be achieved through the combination of functional surfaces and electrothermal de-icing systems. One critical factor is the durability of the coatings.

Project Partners

- FH JOANNEUM GmbH - Coordinator

- Aerospace & Advanced Composites GmbH

- JOANNEUM RESEARCH Forschungsgesellschaft mbH

- Rembrandtin Lack GmbH

- RTA Rail Tec Arsenal Fahrzeugversuchsanlage GmbH

- Villinger GmbH

Funding program: TAKE OFF