Evolution#4 - Development of a fully automated airplane manufacturing technology and implementation of IoT

Short Description

Motivation

The name of this project EVOLUTION#4 shows the dilemma the actual manufacturing is in in context with market estimations and societies challenges. While the demands for effective airplanes rises current CFRP part production is still in pre-industrialized state, with most of the actual work is still done by hand or semi-automated. High demands on material and manufacturing make full automation nearly impossible and conservative construction guidelines are copied to the bionic structure of carbon components losing most of the benefits on the way. And even 6 years after the first flight of the 787 production rates are not nearly efficient and fast enough to produces even 10 ac/month while strategists started tospeak of the demand for 100ac/month.

Objectives

- Research on highly automizable production technologies for aerospace parts and resin systems

- Production technologies for the manufacturing of the Airbus "Wing of Tomorrow"

- Analysis and Concepts on Industrialization and I4.0 concepts for aerospace production

Content

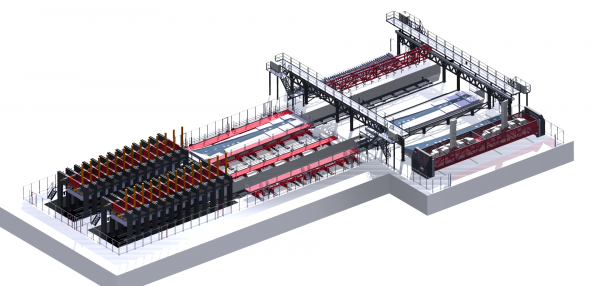

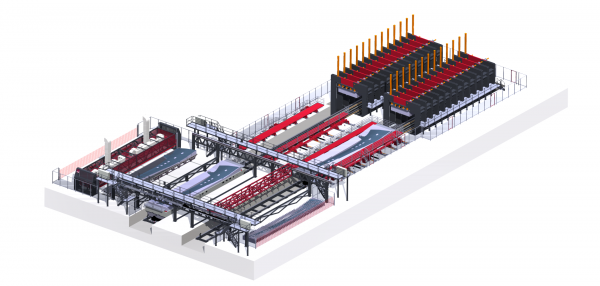

In Evolution#4 an approach for the 4th industrial revolution will be addressed by bringing theproduction of aeronautical structures to a fully automated RTM process. In a holistic approach with leading specialists from Airbus the Austrian consortium will develop intelligent, sensor-based and quality driven production technology and prepare for coming project on the example of the A320 vertical tail plane.

Methodology

Sensor based an quality driven manufacturing technologies and concepts for production lines for wing parts is developed in this project. The Austrian consortium is wporking together closely with Airbus DLR and CTC to develop technologies for structural parts in production szenarions of 100AC/months.

Expected results

Project Partners

- ALPEX Technologies GmbH - Coordinator

- Aerospace & Advanced Composites GmbH

- Airbus Operations Stade

- Brimatech Services GmbH

- Composite Technology Center Stade

- DLR - Deutsches Zentrum für Luft- und Raumfahrt

- Fill Gesellschaft m.b.H.

- Montanuniversität Leoben

Funding program: TAKE OFF